We usually use the scraper is generally divided into ordinary carbon steel scraper and ceramic coating scraper.

Ordinary carbon steel blade mainly used for traditional benzene soluble ink, because of benzene solubility and dispersion are very good, and benzene is lubricating the solvent, so general carbon steel is also possible.

And in the non benzene ink, water soluble ink and alcohol and ester as solvent ink is not smooth, it is relatively easy to produce a knife silk printing problem in printing, customers will choose some ceramic coating scraper (relying on ceramic surface lubricity to reduce scraper and a printing plate roller wear, the ceramic is about 0.5, carbon steel is 0.8), and the composite coating and steel are in contact with the printing plate cylinder, equal to in many times the excess ink scrape. This not only improves the printing quality, but also improves the efficiency of the printing machine.

But prices tend to be high, although the theoretical lifetime of ceramic coating blade is 7 to 10 times the life of ordinary carbon steel, but in the actual operation will appear different rate may be more than 10 times, may also only 1 to 2 times of life, because too many factors, and not scraper and ink for a single factor to decide.

The ceramic coating blade high prices are often confined to the part of the customer or be used in part in the process of.

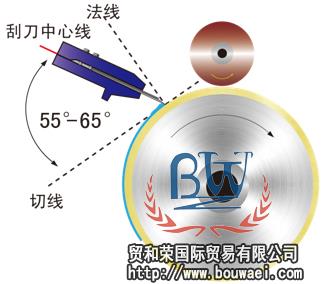

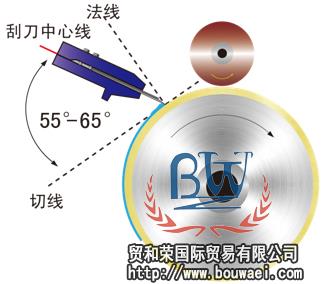

Angle of scraper:

Correct blade angle adjustment, so as to achieve the best printing effect

In gravure printing blade angle of 55 - 65 degrees. A flat angle will produce larger contact area, resulting in paste version and tailing. While the angle is too steep, it is easy to produce a knife.

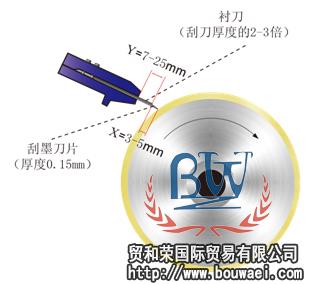

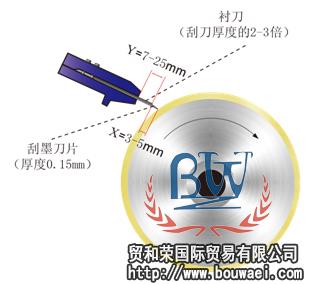

Two. Installation of scraper:

Rigid tool: X = 3mm, can effectively solve the ink scraping phenomenon.

Neutral with a knife: X = 4mm, the standard installation knife.

Soft knife: X = 5mm, is conducive to the network transfer and coarse grain printing (for example: white ink)

Scraper must be installed straight without twists and turns.

Three. Blade pressure:

The pressure of the scraper should be as light as possible.

The blade is thin, the smaller the pressure is. The scraper is required to have a certain toughness to compensate for the deviation of the radial pulsation or diameter of the roller. Too much pressure increases the contact area and the friction force of the roller blade and version of the, can lead to bent blade, serious edge will break and "the wire" phenomenon.